What Is Supply Chain Risk Management?

Supply chains rarely fail in dramatic ways anymore. Instead, problems often build quietly through missed warning signs, hidden dependencies, or outdated assumptions. Supply Chain Risk Management exists to address these silent vulnerabilities before they escalate into costly disruptions.

Rather than trying to predict every possible failure, It focuses on building systems that can withstand uncertainty, adapt quickly, and recover efficiently when disruption occurs.

Understanding Supply Chain Risk Management

Supply Chain Risk Management is the structured and ongoing process of identifying, assessing, and responding to risks across the entire supply chain, from raw material sourcing to final product delivery.

What sets modern Supply Chain Risk Management apart is its expanded scope. Today, risks extend beyond suppliers and logistics to include:

- Data accuracy and system reliability

- Regulatory and geopolitical changes

- Cybersecurity exposure

- Environmental and climate-related events

- Human decision-making under pressure

In essence, Supply Chain Risk Management is about managing uncertainty at scale, not just reacting to isolated incidents.

Why Traditional Approaches to Supply Chain Risk Management Fall Short

Many organisations still rely on static risk assessments, annual reviews, supplier scorecards, and predefined contingency plans. While useful, these methods struggle to keep up with the complexity of global supply networks.

A critical insight:

Most supply chain disruptions are not caused by unknown risks, but by known risks that were underestimated or deprioritised.

Effective Chain Risk Management requires continuous monitoring and the ability to adjust decisions as conditions change.

Overlooked Risks in Modern Supply Chain Risk Management

Beyond well-known risks such as delays or supplier failures, several less visible threats can undermine supply chain stability:

Dependency Risk

Multiple suppliers may rely on the same sub-supplier, region, or infrastructure, creating a single point of failure.

Information Lag

Decisions made using outdated or incomplete data can magnify disruption instead of containing it.

Behavioral Risk

Human bias such as delaying escalation or overconfidence in past performance often weakens response efforts.

Compliance Drift

As regulations evolve, internal processes may lag behind, creating exposure without immediate warning.

Recognizing these hidden risks is a core function of Supply Chain Risk Management.

The Core Goal of Supply Chain Risk Management:

The goal of Supply Chain Risk Management is not to eliminate all risk an impossible task in today’s environment.

Instead, it aims to:

- Improve visibility into potential vulnerabilities

- Define acceptable levels of risk

- Enable faster, coordinated responses

- Strengthen recovery and continuity

A resilient supply chain is not risk-free; it is prepared.

Supply Chain Risk Management as a Driver of Stability and Growth

Organizations that invest in Supply Chain Risk Management gain more than protection. They gain agility and trust.

Strong risk management enables businesses to:

Better decisions under pressure: Supply Chain Risk Management improves decision clarity, helping leaders act faster without guesswork.

Controlled risk-taking: It shows which risks are acceptable, allowing businesses to move forward while competitors hesitate.

Fewer costly overreactions: Structured risk insight prevents panic decisions like excess inventory or rushed supplier changes.

Stronger supplier trust: Open risk awareness builds cooperation instead of conflict with key suppliers.

Invisible brand protection: Consistent fulfilment protects customer trust even when disruptions don’t make headlines.

Internal alignment: Shared risk visibility reduces friction between procurement, operations, and leadership.

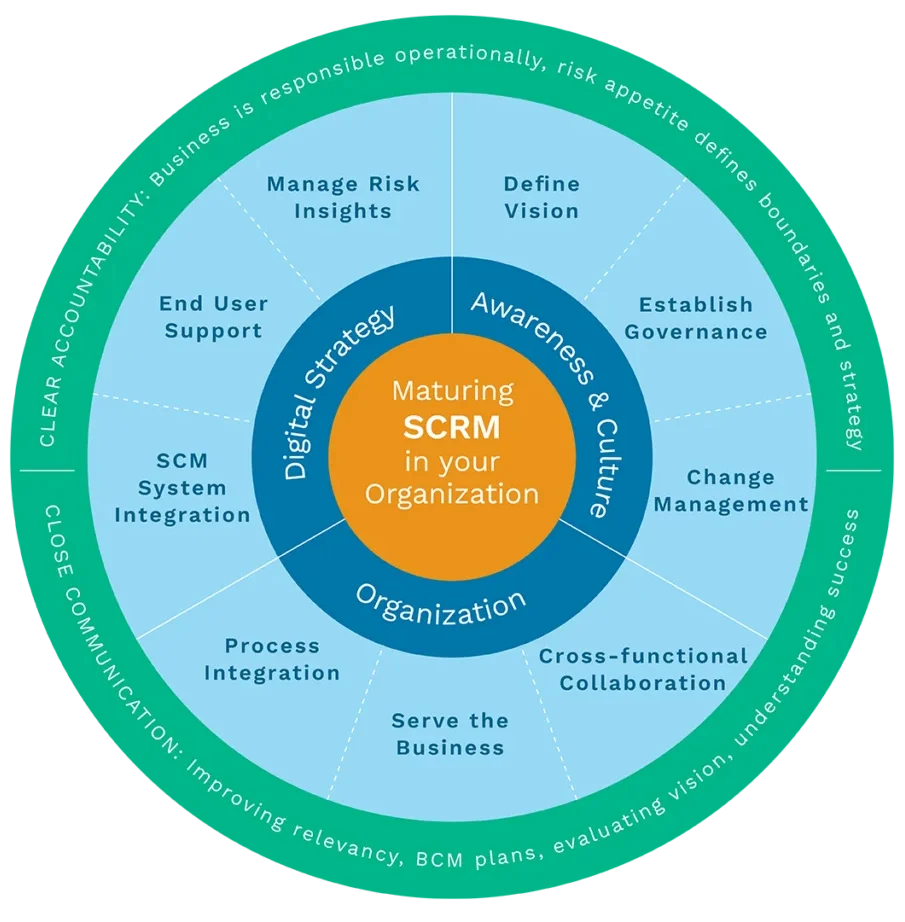

Core Elements of an Effective Supply Chain Risk Management Approach

A successful Supply Chain Risk Management strategy typically includes:

End-to-End Visibility

Understanding direct suppliers as well as extended supply networks.

Scenario Planning

Preparing for plausible disruptions, not just likely ones.

Early Warning Signals

Tracking indicators such as supplier financial health, geopolitical shifts, and climate patterns.

Cross-Functional Collaboration

Risk management spans procurement, operations, finance, IT, and leadership.

From Cost Optimization to Resilience

For years, supply chains were designed primarily for cost efficiency. Today, businesses recognise that efficiency without resilience creates vulnerability.

Supply Chain Risk Management supports a balanced approach, one that considers:

- Long-term stability over short-term savings

- Diversification instead of over-reliance

- Resilience as a strategic investment

This shift allows organisations to operate confidently in an unpredictable world.

How SignalX contributes to Supply Chain Risk Management

SignalX strengthens Supply Chain Risk Management by providing early risk visibility, continuous monitoring, and data-driven supplier intelligence. It helps organizations identify hidden supplier risks, monitor financial, compliance, and reputational signals in real time, and make faster, more confident decisions before disruptions escalate. By automating due diligence and standardising risk insights, SignalX enables more resilient, compliant, and proactive supply chains.

See Supply Chain Risk Management in action. Book a SignalX demo today.

FAQ

1. What is Supply Chain Risk Management (SCRM)?

Supply Chain Risk Management is the process of identifying, assessing, and mitigating risks that can disrupt supply chain operations, such as supplier failures, logistics delays, or geopolitical issues.

2. Why is Supply Chain Risk Management important?

It helps businesses minimise disruptions, reduce financial losses, ensure continuity, and maintain customer trust during unexpected events.

3. What are the common types of supply chain risks?

Common risks include supplier risk, operational risk, logistics risk, cyber risk, compliance risk, and external risks like natural disasters or political instability.

4. What is the difference between supply chain risk and vendor risk?

Vendor risk focuses on individual third parties, while supply chain risk considers end-to-end dependencies, including logistics, sourcing, and distribution networks.

5. What is the purpose of Supply Chain Management?

The purpose of Supply Chain Management (SCM) is to ensure the efficient flow of goods, services, information, and finances from suppliers to end customers. It helps organizations reduce costs, improve operational efficiency, manage risks, and deliver products on time while maintaining quality and customer satisfaction.

6. What is Supply Chain Management in marketing?

In marketing, Supply Chain Management focuses on aligning product availability, delivery speed, and customer demand with marketing strategies. It ensures that products are available at the right place and time to support promotions, enhance customer experience, and strengthen brand reliability.