6 Stages of Vendor Development: Best tips to choose your true vendor

Without a question, vendors play a crucial role in every organization’s success. When confidence is high, and the quality and timeliness of the goods and services delivered by your vendors surpass your expectations, they can operate like a well-oiled machine.

Or they could turn into a hassle, eat up valuable resources, and cost your company tens of thousands of dollars in administration and performance monitoring.

Like the majority of buyers and importers, you probably fall somewhere in the middle of these two extremes.

However, there is still hope for establishing excellent vendor development. If you follow this step-by-step procedure, vendor development will quickly pay off for you.

Who is a Vendor?

A vendor, sometimes known as a vendor, is a third-party organization frequently employed to carry out duties that a business outsources. Vendors might be either an organization with several employees or a lone individual. Companies may also decide to employ contractors to assign crucial jobs that their team requires assistance with.

Since vendors frequently finish a single job and are not salaried workers, using them might help a business save money. Vendors can offer crucial services and help companies that are struggling to meet client demand. Vendors that companies may use include:

- Retailers

- Manufacturers

- Software developers

- Wholesalers

- Maintenance providers

On behalf of a business, vendors can also carry out duties like producing brochures for marketing campaigns or tidying up after events. Additionally, companies may hire suppliers to deliver or install computers, buy office furniture, and place orders for janitorial supplies.

What is the Vendor Development Process?

The vendor development process is a sequence of actions that a corporation takes to discover, analyse, and choose vendors to offer goods or services to the organisation. The vendor development process aims to establish long-term, mutually beneficial relationships with vendors that can meet the company’s demands in a cost-effective and reliable manner.

Effective vendor development is crucial to the success of any business because it ensures that the firm has the resources it needs to function efficiently and effectively while also avoiding risk and maximizing value.

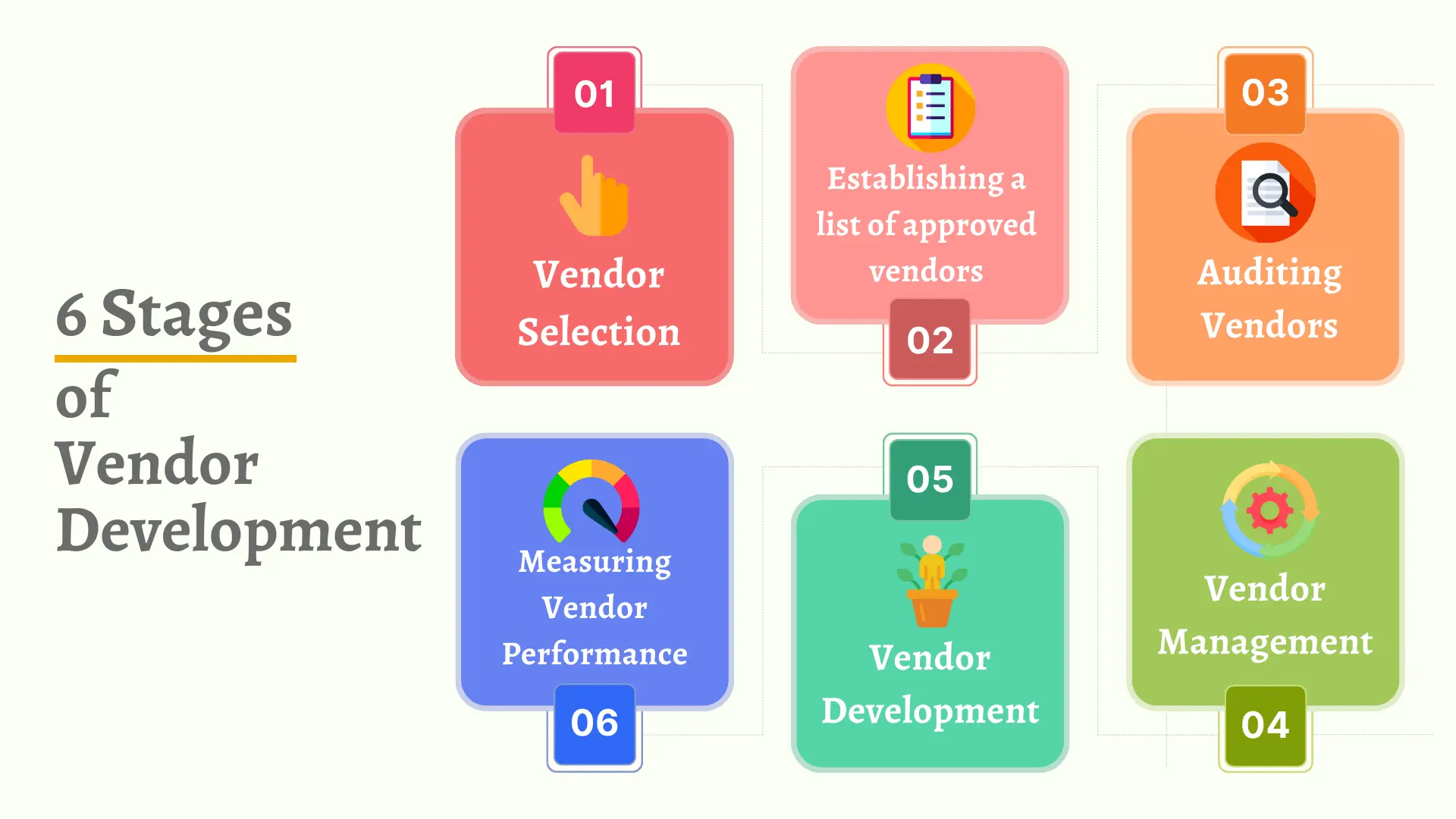

6 Stages of Vendor Development

1. Vendor Selection

Your business depends on your choice of vendors. Additionally, classifying your supply base will help you manage those vendors’ resources more efficiently and get the most out of them.

It would be ideal if all of your suppliers produced excellent work. However, businesses may have lengthy vendor lists that number in the thousands, some of which are obviously more important for quality than others. Therefore, for active vendor development management, selection should come first.

When starting their search, importers and buyers frequently take into account many factors in vendor development for assessing possible sellers, such as:

- Minimum order quantity (MOQ): smaller customers or those on a tight budget will be particularly attentive to the minimum order quantity (MOQ) a vendor requires.

- Payment terms: When choosing a vendor, importers of all sizes may take payment terms into consideration.

- Certifications: You could find value in typical certifications like ISO 9001 and ISO 14001. However, keep in mind that certificates might not always be reliable, particularly in developing nations like China or Vietnam. An on-site audit is the best way to confirm this.

- Production capabilities and capacity: this is a simple aspect, but many companies are unsure how to verify it. Among the most reliable methods are requesting and approving a pre-production sample and conducting an on-site audit.

The selection criteria differ from company to company. They are also influenced by the quality standard you have established for your business model, as well as your organization’s aims and rules.

2. Developing An Approved Vendor Development List

We frequently discover that a company’s supply base grows with time. Therefore, using a “second source supply” for “risk management” is a very wise business strategy.

However, it is occasionally a good practice to assess your supplier base and consolidate the number of vendors you have to maintain, which is an expense in and of itself.

Every company should use its approved vendor development list and track its performance in terms of pricing, quality, and delivery. As previously noted, categorizing your vendors will make this a more efficient and value-added activity.

Categorizing vendors by criteria

Your vendor development list should be divided into categories based on the following criteria:

- Vendor type – crucial, tooling, office supplies, maintenance, and training

- Spending tiers: high, medium, and low

- Frequency of use – frequently, infrequently, rarely

- Second source vendor – yes or no

Filtering information in the approved list to manage vendor development

By adding these categories to the vendor development list, you can then filter this information in a variety of ways to find:

- The top five most expensive vendors

- Top ten critical vendors

- Critical vendors with no backup

- Vendors who are rarely used and have little expenditure

A categorized list becomes a valuable tool for managing vendors and maximizing your resources to get the most benefit out of your supply chain.

The list will assist you in developing the most effective audit schedules that will have the biggest impact on the performance of your vendors and hence your own business.

3. Auditing Vendors

Vendor audits, like most audits, are a snapshot in time. This method can collect a lot of information, and it is a need for most quality management systems (QMS). Vendor audits are classified into two types:

Questionnaire-type vendor audits

The questionnaire, sometimes known as a phone call audit, is well-known among sourcing specialists. It’s a first step that typically saves time by allowing you to vet vendors swiftly.

Questionnaires are useful in vendor development for gathering basic factual information about an organization rather than judging how successful and efficient its operations are. For example, a questionnaire would provide answers to questions such as:

- “What standards do you have for quality?”

- “How many staff members do you have, and how many of them are involved in quality control?”; and

- “What kinds of industries, and in what numbers, do you supply?”

A questionnaire-style audit can gather information effectively, but its fundamental drawback is that the data is unreliable. You’ll probably be relying on a vendor sales representative, who might just be saying what they believe you want to hear.

Additionally, the range of data you can learn through a straightforward questionnaire-style audit is constrained. Therefore, the most effective method for obtaining accurate and detailed information is often an on-site vendor audit.

On-site vendor audits

Of course, on-site auditing would give you all the details from a questionnaire-based audit and much more, like:

- The QMS organization of the business.

- Information on performance.

- Management of products and processes.

- Results of certification audits and internal vendor audits.

- A tangible sense of the company’s operations and the culture it fosters.

- Personal contact with important employees of the vendor.

There are a few methods you might use to carry out this audit.

Performing your own informal audit during a vendor visit

One method is to perform an informal audit of your vendor while you are at their premises. Just by taking a glance around the production area, warehouse, and other grounds, you can get a lot of insightful information.

You don’t need to be an expert auditor, for instance, to see when a factory is blatantly chaotic, neglects to maintain production equipment, or employs workers in hazardous working circumstances. Additionally, a visit frequently makes it clear right once whether a vendor:

- Is the seller (middleman) or the manufacturer (factory); and

- Can genuinely produce or supply the item you’re looking to buy

This type of informal audit has a major drawback in vendor development as the vendor is likely to have control over what you see there. For example, they can instruct employees on how to respond to any inquiries you may have and restrict your tour to only the parts of the plant they think you should see.

The other drawback is that you might not possess the knowledge required to carry out an exhaustive audit. Results from a qualified auditor typically have much more specific information than those from a novice importer or purchaser. Mainly when using a particular compliance framework like Sedex or C-TPAT, this is valid.

Keep in mind that continuous auditing is the most efficient auditing method. For whatever reason, an audit is conducted every time you visit a vendor.

By examining the data in the approved vendor development list and key performance indicators (KPIs) data, including “right first time,” “delivery on time,” and other metrics, you’ll be able to manage vendor audits and factory visits in advance in the most effective way.

4. Measuring Vendor Performance

If your technologies enable making the information freely accessible, you may easily assess vendor performance. And if properly applied, KPIs will develop into a very potent instrument. Vendor KPIs are an effective way to gauge a vendor’s overall performance, including:

- Right first time

- Delivery on time

- Response time, quotes, and inquiries

- Defect rate

- Inspection and auditing results

Tracking vendor performance through a third-party QC partner

Most small and mid-sized businesses don’t invest in their own integrated enterprise resource planning (ERP) software, despite some large purchasers doing so.

However, an increasing number of impartial inspection and auditing companies provide access to regular reporting of vendor performance metrics and product quality.

The digital solutions that these companies offer vary. Some merely provide cloud-based access to earlier audit or inspection reports. Others provide a thorough analytics dashboard with a plotted breakdown of quality issues by vendor, product type, SKU, and severity.

Whether obtained through a third-party solution or your own digital ERP, clear and combined vendor performance data can significantly aid in vendor development and ongoing quality improvement.

5. Vendor Development

Some larger companies will have a dedicated staff of vendor-quality engineers who work mostly in-house, rather than at vendors’ facilities, and spend the majority of their time there. This defeats the goal of vendor development quality engineering.

In order to have the greatest impact and influence on “right the first time” quality, the engineer should spend the majority of his or her time at the vendors’ facilities. Smaller businesses, in particular, need to approach this carefully and use all the information at their disposal to make wise decisions regarding vendor status.

The value of personally visiting your vendors For Vendor Development

Even if your company is small, you still need to set aside time to visit vendors for better vendor development, go over their specifications, and clearly outline your organization’s deliverables and expectations.

Create an agenda in advance and make sure to plan each visit thoroughly. For example, this is one of your most important suppliers. In that case, you should stay a few days and walk through the entire process with them, including design, manufacturing, inspection, packaging, delivery, etc.

Make the most of your visit, and you can leave with the assurance that everyone is aware of what is required. Nothing compares to taking the time upfront with your vendors to prevent issues later.

6. Vendor Management

The ongoing management should be customized to meet the requirements of each vendor once the development stage has reached an acceptable level of maturity.

To understand each vendor’s needs and any necessary corrective actions, it is essential to monitor vendor performance continuously.

For instance, seasonal variations in a single vendor’s production capacity may cause delays in delivery. You can prevent more disruptions at that plant by taking necessary action by monitoring on-time delivery over time.

Similar to how current quality reporting can assist you in identifying and resolving product problems that keep happening at particular plants. Better vendor development management tactics are made possible by this transparency.

Additionally, by managing your current vendors well, you may make educated decisions about whether to keep working with a certain vendor, get rid of them, or have them expand their services in order to serve your company’s needs better.

Tips for Choosing Vendors

Before entering into any contracts, take the following advice to make the best choice possible:

Research each vendor

Proposals may contain a lot of details regarding the services provided, but it’s also crucial to look into each vendor’s background outside of the RFP.

Verify dependability

Businesses need to investigate and confirm project fulfillment. Verify with the vendor’s previous clients that projects were completed on schedule and within the allotted budget.

Verify the product’s quality and value

Since certain merchants may offer tangible goods, it may be crucial to check the item before offering it to clients. In addition, companies can wish to guarantee that each product is of the same caliber as those that came before and after it.

Identify experience

It’s possible that some vendors have a long history of offering customers high-quality goods and services. By selecting an experienced vendor, you can be sure that the work will be done on schedule and to your company’s standards.

Communicate effectively

Without clear communication, there might be disagreements regarding what needs to be done, when it should be done, how should it be done, and other crucial project-finishing factors. However, both parties must concur for you to fully understand what you are getting into when making your decision.

Conclusion

One of the most crucial aspects of production is sourcing, the process of finding the correct providers. Your suppliers directly affect the quality of your goods and services. Later in the process, “fighting fires” is expensive, wasteful, and almost always results in customer unhappiness (in one way or another) and revenue loss.

Start by deciding which vendors most closely fit your requirements. Then, create a list of categories for your merchants to make organization easier. Then, vet each vendor by calling them and asking pertinent questions, or better yet, go in person and do a more thorough audit there.

By examining their KPIs, you may gauge your vendors’ performance and evaluate each one impartially. Work closely with your suppliers to build trust and raise the standard of your work. You can decide which needs more development and which makes the cut by following all of the procedures mentioned earlier.

Spend time getting to know your vendors, keep open lines of communication, talk to the appropriate individuals, and keep things clear. Vendors are a vital component of your success. And who you choose to collaborate with will determine whether you succeed or fail.

Ready to Improve Your Vendor Relationships?

Take your vendor development process to the next level. Download our comprehensive guide today!

FAQs

1. What are the six stages of vendor development?

Think of vendor development as a progression:

- Discovery — find potential suppliers;

- Vetting — check capability and compliance;

- Approval & Onboarding — formalize contracts and processes;

- Enablement — train and align them to your standards;

- Performance Improvement — run improvement projects and monitor KPIs;

- Ongoing Management — renew, scale, or phase out relationships based on results.

2. How do I quickly identify suppliers worth developing?

Focus on strategic fit: the right product/service fit, capacity to scale, cultural alignment, and baseline compliance. Use a short qualification checklist (capacity, certifications, lead times, basic financial health) to separate promising vendors from low-priority leads.

3. What should an approved vendor list look like?

Keep it simple and dynamic: categories (preferred, qualified, contingency), key contact info, capability notes, and review dates. Make it a living document you update after audits, proof orders, or performance reviews.

4. Why conduct vendor audits isn’t paperwork enough?

Audits reveal reality: they verify on-site processes, quality controls, labor practices, and health & safety things that documents can’t fully prove. Audits uncover systemic risks early so you can prevent supply disruptions or brand damage.

5. Which vendor metrics actually move the needle?

Track outcome-oriented KPIs: On-time-in-full (OTIF), defect escape rate, lead-time variability, corrective action closure time, and cost of poor quality. Add a compliance score (licenses, certifications) to capture regulatory risk.

6. How do you run a vendor development program that works?

Start with a capability gap map, set measurable targets, run short improvement sprints (pilot runs, 30/60/90 day plans), and offer hands-on support (training, tooling, shared SOPs). Tie supplier incentives to measurable outcomes, not just promises.

7. How can I help a small supplier scale without risking my operations?

Use staged commitments: pilot orders → ramp plans → capacity stress tests. Provide playbooks, share forecasts transparently, and consider dual-sourcing critical parts until the supplier proves consistent performance.

8. What role does technology play in vendor development?

Use a supplier portal or shared dashboard for scorecards, PO tracking, and CAPA (corrective action) status. APIs and automated alerts cut manual work and make performance problems visible early.

9. Will vendor development actually reduce costs?

Yes, by reducing defects, late deliveries, and emergency freight. Better vendors mean fewer production stops, lower rework, and stronger negotiating power all of which lower total cost of ownership over time.

10. What are common vendor development mistakes to avoid?

Don’t over-rely on one measurement, skip verification, or expect instant change. Avoid unclear requirements, no follow-through on corrective actions, and ignoring supplier financial health any of which undermines long-term gains.