Supplier Scorecards: Your Key to Ethical and Efficient Sourcing

A supplier scorecard, also known as a vendor scorecard, is a document that allows a company to track a vendor’s performance and effectiveness over time. The scorecard divides supplier performance into quantifiable categories and criteria. A supplier scorecard, for example, may include metrics for grading product quality, vendor delivery, cost, and customer service.

Who uses a supplier scorecard?

Procurement and strategic sourcing managers are the most common consumers of supplier scorecards. While these managers are typically the primary administrators, other major company stakeholders may be involved in supplier scorecarding as well. Supplier scorecard users will also report scorecard findings to their company’s leaders, such as supply chain health and vendor value.

When and How to Use Supplier Scorecards?

Supplier scorecards are used to track, manage, and measure vendor performance. This includes benchmarking supplier performance against specified indicators, creating goals, and improving supplier performance over time.

A scorecard can be used in a variety of ways. Here are several examples:

- Negotiating with an existing supplier: A scorecard can be used to show areas where a supplier has to improve in order for you to continue doing business with them. It can help you acquire a better price or more favorable terms for direct or indirect procurement.

- Choosing a new vendor: Use a scorecard to evaluate a potential vendor’s performance to that of your present suppliers when deciding whether to work with them. This will allow you to shorten your vendor approval process and make an informed decision about whether to collaborate with the new provider.

- Identify potential hazards: A vendor scorecard can aid in the identification of potential risks connected with working with a specific supplier. This encompasses financial stability, supply chain hazards, product or service quality, and delivery times.

One of the most typical uses of supplier scorecards is to track the performance of your vendors over time. This data can be utilized to identify areas for improvement and create action plans to increase performance.

Benefits of a Supplier Scorecard

To ensure your success, we have identified the following key benefits of the exercise:

Effective Performance Management

A supplier scorecard can help to streamline the process of identifying suppliers who are leading or trailing.

Having a scorecard aids in the identification of poor performance and the recommendation of corrective action. SCARs, or Supplier Corrective Action Requests, are issued as formal communication when supplier performance deteriorates. Similarly, scorecarding is used to identify the best suppliers, and buyers can efficiently prioritize these supplier relationships.

These providers may also be rewarded with additional commercial possibilities, strategic collaborations, or certifications.

Objectivity

A supplier scorecard enables a data-driven, objective approach to supplier performance evaluation. It also lowers the danger of supply chain management errors and personal biases. Scorecarding increases transparency in performance management and evaluation for suppliers. Suppliers can precisely compare their performance to their historical performance and, in some cases, to other suppliers in the same market.

For new requisitions, scorecard data should be a crucial factor in the supplier selection process. Suppliers who consistently deliver good results should be recognized.

Tracking and Benchmarking

Buyers can also use scorecarding to examine supplier performance patterns over time. This study can serve as a crucial indicator of possible problems as well as an important input for insights. Scorecards can be used to index providers, improve procurement decision-making, and benchmark performance for comparison.

Specificity

Scorecards, in addition to being an analytical tool, aid an organization in self-evaluation. Customizing the supplier scorecard allows procurement to manage, monitor, and maintain alignment with corporate objectives.

Negotiation Assistance

Pricing and price fluctuation data acquired via scorecarding can also be used to support current and forthcoming vendor negotiations.

Aid in Decision Making

Supplier Scorecard aids in the visualization of data and the gathering of insights to enable corrective action and the simplification of internal decision-making.

Improve collaboration

Scorecards promote transparency and constant contact between vendors and buyers. This, in turn, is critical for bettering supplier connections. Scorecards are not designed to be stand-alone tools; procurement will get the most value if the supplier scorecarding is completely incorporated into regular operations and vendor management.

How to create a supplier scorecard

The weighting of key performance indicators (KPIs) is determined by the company’s objectives. Some organizations, for example, base their name on sustainable materials, making quality sourcing more important than the lowest price.

To select supplier quality evaluation variables, first, prioritize your goals and objectives. A huge box shop chain like Walmart may prioritize pricing, quantity, and availability, but The Honest Company’s brand is built on ecologically friendly ingredients and ethical sourcing. Even within the same industry, the relative importance of each factor may change dramatically amongst rival firms.

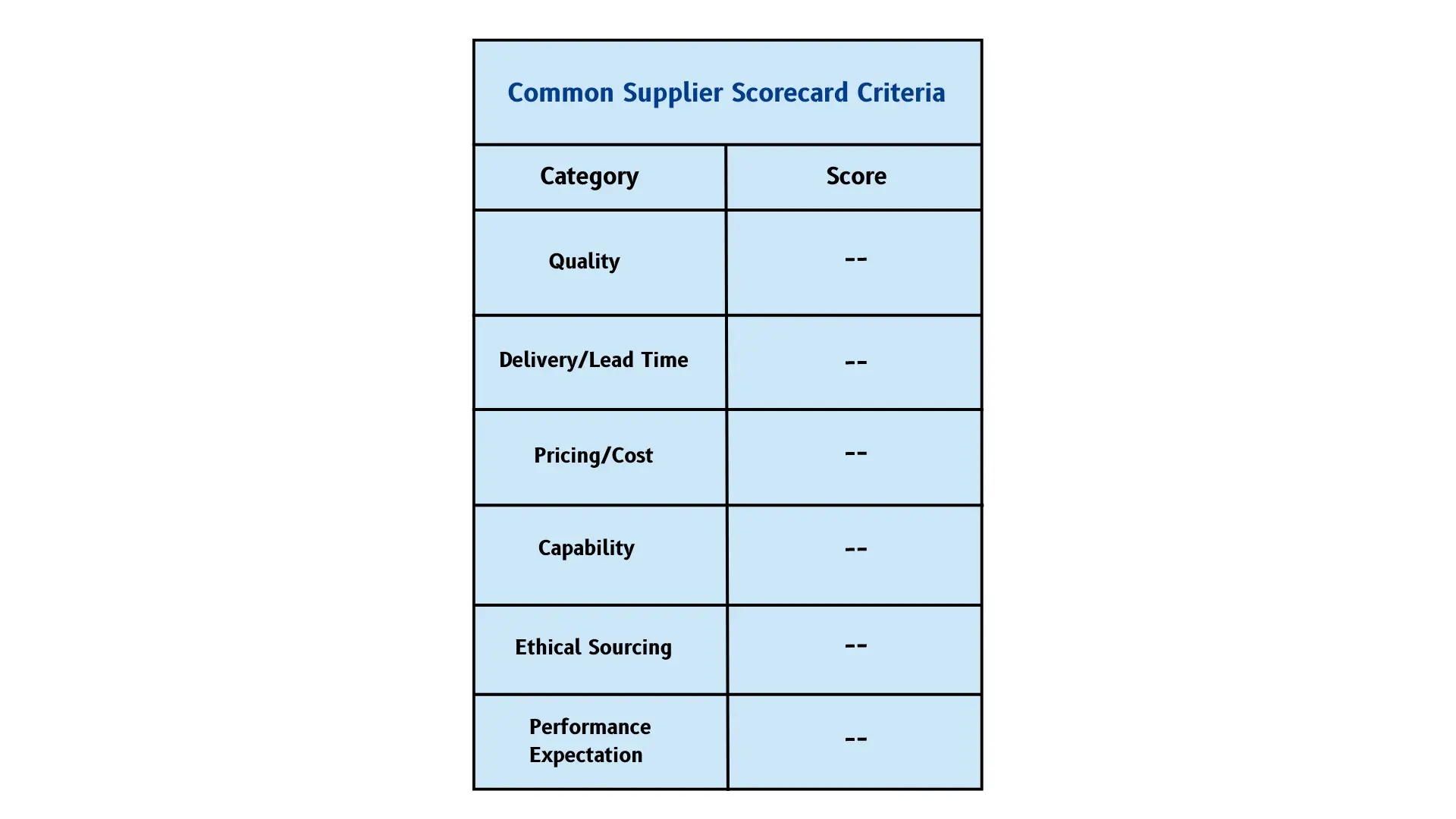

Common Supplier Scorecard Criteria

Scorecard construction can begin once the company’s goals and objectives in relation to supplier evaluation have been identified and prioritized. Most organizations will have intersecting performance measurement criteria, which will be arranged in descending order of priority. Here is a list of some of the most common factors:

Quality

Quality of goods and services is high on the priority list for practically every firm. An organization is only as good as the raw materials, services, or items for sale that make up what is offered to clients and customers.

The quality evaluation comprises determining if the product fits the contract specifications, the condition in which it is delivered, the rate of return (customer satisfaction), and whether the product achieves sales expectations.

Poor quality raw materials, for example, in the construction business, can lead to building foundations that do not fulfill safety compliance criteria, which can swiftly jeopardize any project.

Even when selecting technology to increase efficiency, reviewing performance criteria is crucial to success. Adopting software systems that do not suit organizational needs or are too difficult to implement easily might have the opposite effect, adding man-hours, diminishing visibility, and imposing workarounds as staff battle to comply.

Delivery/Lead Time

It can be difficult to determine delivery timings at first. From the perspective of a supplier, delivery occurs when a shipment leaves the warehouse. It is when the items are received and logged from the perspective of the receiver.

To guarantee that vendors deliver on time and within budget, delivery indicators should be tracked and analyzed over time. Comprehensive procurement software provides the tracking data required, as described by the parameters that are set.

Pricing/Cost

While every company wants to pay the lowest feasible price, and pricing appears in practically every charted example, it is not always a statistic that should be included. Cost should not be a priority unless your brand is established at low prices.

Larry Fast, Founder & President of Pathways to Manufacturing Excellence, says in a recent Industry Week piece that cost should not be included in supplier evaluation because price negotiation is dependent on external market factors and has no role in upgrading processes to excel.

Capability

Can the provider regularly supply the required quantity of product? Monitoring suppliers’ financial stability, production competence, and adaptability all contribute to managing supply chain risks.

Ethical Sourcing

Ethical sourcing is becoming more crucial in competitive business strategy. Corporate social responsibility (CSR) is identified by Gartner as an “important market differentiation for organizations as more customers prefer to acquire products from companies that act responsibly.”

This is by no means an exhaustive list of factors to consider. Achieving a balanced scorecard is dependent on the specific needs, budget, and objectives stated by the organization. Other factors to consider are innovation, new product creation, communication, corrective measures, response time, and flexible distribution options. More granular breakdowns within each broad area might be awarded weight for a total score for that statistic.

Define Expectations

Most organizations reduce the list to four or five important topics and request that favored suppliers work on improving in those areas for mutual benefit. Supplier performance expectations and actionable goals can be defined using the criteria for continuing supplier evaluation.

Define particular, observable metrics for tracking after determining broad categories and weighting factors with respect to importance. The technique for supplier scorecard measurements should clearly identify what constitutes good, acceptable, and unsatisfactory performance limitations for each category.

Partnering with Major Suppliers to Improve Metrics

Finally, companies can actively participate in assisting large suppliers in developing an executable plan for continuous improvement to ensure the success of a vendor scorecard program.

Procurement managers can greatly increase supply chain efficiency by aligning supplier scorecard indicators with business goals and objectives, as well as communicating performance expectations and evaluations internally and with suppliers.

When looking for new suppliers, scorecards also give a baseline comparison. Procurement managers can reduce risk by finding new suppliers with the purpose of filling holes left by current vendors.

Metrics for Determining Scorecard Specifics

Many corporations create equations to provide hard data in order to quantify vendor performance. Here are a few samples to aid you with your scoring:

Quantity:

- Monthly Quantity Rejected ÷ Monthly Quantity Delivered = Total Monthly Deliveries

- Rolling Quarterly Quantity Rejected ÷ Rolling Quarterly Quantity Delivered = Total Rolling Quarter Deliveries

Lead Time:

- Real Lead Time – Starting Lead Time = Amount of Improvement

KPIs for Supplier Scorecards

A supplier key performance indicator is a measurable metric that reflects how well a company’s supplier performance propels it to reach its strategic business objectives.

Here are the key KPIs to consider while developing your supplier scorecard:

- The number of vendors: Keep track of your reliance on individual vendors and reduce redundancies.

- Compliance Rate: How effectively do vendors meet company, safety, or legislative requirements?

- Purchase Order Cycle Time: Learn about lag times and how they affect your business.

- Vendor Availability: Assess a vendor’s on-demand response capacity and ability to scale in response to your company’s and customers’ needs.

- Product Defect Rates: To calculate defect percentages, determine your present levels and breaking point.

- Error Rates: Determine how frequently a provider delivers wrong goods or services.

- Material flaws: Ensure that the supplier employs the right grade and value for manufacture.

- Competitive Lead Times: Determine the overall time required to complete an order.

- Purchase Order Cost: Keep track of the internal costs associated with each purchase.

- Procurement Cost Reduction: Use accumulated data to reduce potential future excess expenditures.

- Procurement ROI: Calculate the return on investment of a specific supplier.

- Continuous Improvement: Evaluate a vendor’s commitment to incremental or breakthrough improvement.

What is the balanced supplier scorecard approach?

The balanced scorecard methodology uses four distinct measurements, or, as we can see, four perspectives. These are used to assess performance across the entire supply chain. These four indicators bring together the supply chain strategy and vision.

The four metrics are listed below, and firms should always ask themselves the following questions before proceeding:

- Financial: How should businesses appear to their shareholders in order to flourish financially?

- Customer: How should businesses seem to their customers in order to attain our vision?

- Internal Business Processes: What business processes must organizations excel at in order to satisfy their shareholders and customers?

- Learning and Growing: How will organizations sustain their ability to change and improve in order to realize their vision?

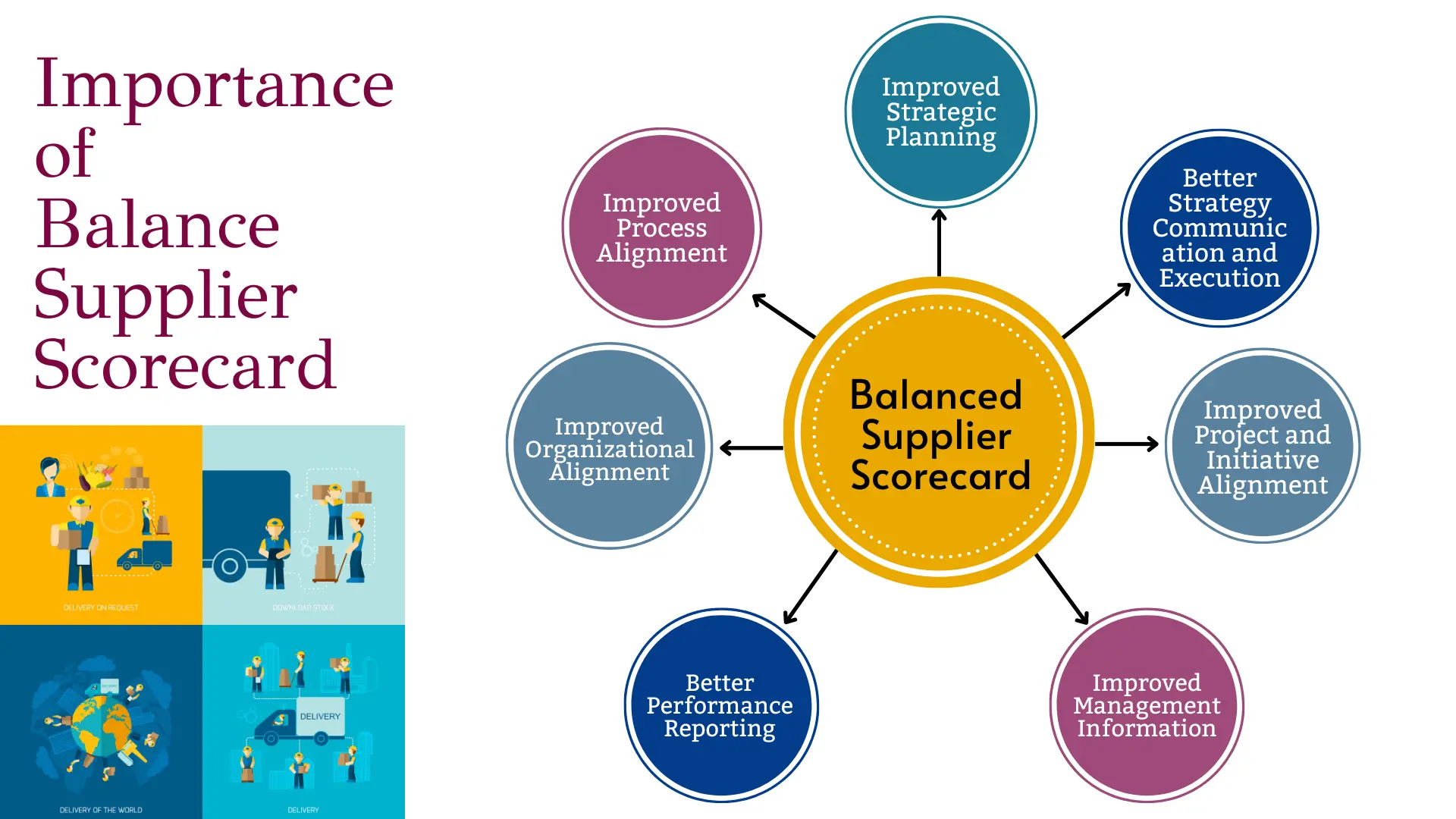

Why is a balanced supplier scorecard important?

-

Improved Strategic Planning

The Balanced Scorecard is an effective framework for developing and conveying strategy. The business model is depicted in a Strategy Map, which assists managers in considering the cause-and-effect links between the many strategic objectives. The process of developing a Strategy Map secures agreement on a set of interrelated strategic objectives. It entails identifying key facilitators or drivers of future performance as well as performance outcomes to build a holistic picture of the strategy.

-

Better Strategy Communication and Execution

Companies can simply communicate strategy internally and externally when they have a one-page picture of it. For a long time, we have understood that a picture is worth a thousand words. This ‘plan on a page promotes strategy comprehension and aids in engaging personnel and external stakeholders in strategy delivery and review. It is important to remember that it is difficult for people to assist in the execution of a strategy that they do not completely comprehend.

-

Improved Project and Initiative Alignment

The Balanced Scorecard assists organizations in mapping their projects and initiatives to various strategic objectives, ensuring that projects and initiatives are tightly focused on fulfilling the most strategic objectives.

-

Improved Management Information

The Balanced Scorecard technique assists organizations in developing important performance indicators for their many strategic goals. This guarantees that businesses are measuring what is important. According to research, organizations that use a BSC method report higher quality management information and make better decisions.

-

Better Performance Reporting

The Balanced Scorecard model can be used to help build performance reports and dashboards. This guarantees that management reporting focuses on the most essential strategic concerns and assists organizations in monitoring plan execution.

-

Improved Organizational Alignment

The Balanced Scorecard allows businesses to better match their organizational structure with their strategic goals. Organizations must guarantee that all business units and support departments are working toward the same goals in order to successfully execute a strategy. Cascading the Balanced Scorecard into those units will assist in doing this and connecting strategy to operations.

-

Improved Process Alignment

Balanced Scorecards, when properly implemented, also aid in aligning organizational operations such as budgeting, risk management, and analytics with strategic priorities. This will aid in the development of a truly strategy-focused organization.

How does a balanced supplier scorecard improve performance?

The supplier-balanced scorecard’s objective is to effectively express expectations, and supplier performance, and as a tool to compare suppliers.

The scorecard is divided into four primary categories (Quality, Cost, Delivery, and Responsiveness) and is calculated after deducting any High Impact or Non-Compliance deductions. Bonus points may be given for outstanding launch performance, cost management, or quality enhancement.

Q + C + D + R + Bonus – (Deductions) = Total Score

Scorecard Period

The supplier scorecard is updated monthly using data from the previous six months. Suppliers will be assigned a monthly and six-month score, with a maximum of 100 points each. Suppliers who do not have 6 months of data will not obtain an overall score for 6 months.

Supplier Performance Levels

The Supplier Scorecard performance levels are used to compare suppliers as a measurement tool. The 6-month overall score is used to calculate performance level scores.

Green – 85 – 100

Yellow – 70 – 84

Red – 0 – 69

Supplier Scorecard Best Practices

Vendor management is an excellent strategy to reduce costs while keeping strong supplier relationships. It is critical to align your scorecard with supplier management best practices. Here are four excellent practices for producing vendor scorecards that matter to your company.

Digitize and automate

Manually tracking supplier data becomes difficult as your organization grows. A digital solution will streamline workflows and free up your time to focus on value-added activities. For example, Ramp’s vendor management function consolidates all of your vendor spending into one dashboard.

To streamline procurement, you can monitor spending trends and upcoming vendor expenses. You will also discover redundant spending and shadow IT, which enhances corporate risk.

Collaborate

While your company comes first, you cannot succeed without vendor support. Before creating new standards, collaborate with your vendors and communicate your expectations to better understand their concerns and challenges. In turn, your vendors will understand your requirements. As a result, you’ll have more realistic criteria to work with your vendors.

Compared to industry norms

Compare your vendors’ KPIs and spending to industry benchmarks to see whether there is space for improvement. For example, one of your vendors may be responding to your issues on time but slower than industry standards.

In this instance, you must increase your KPI thresholds to align with benchmarks. As a result, your vendor scorecard and vendor management system will assist you in remaining competitive.

Connect incentives and penalties to KPIs

Only by linking KPIs to incentives and penalties can your vendor scorecard assist you in making objective decisions. Incentives are an excellent method to match your suppliers with your business objectives. For example, you can recognize excellent vendors by adding them to your favorite supplier list and paying their invoices more quickly than usual.

Penalties may appear harsh on the surface, but most vendors will endeavor to improve performance if they are linked to KPIs. Effective punishments include reducing future orders and removing suppliers from favored supplier lists.

Making vendor-related decisions based on “gut instinct” or “feel” diminishes openness in your vendor performance processes and leads to supplier unhappiness. Instead, back up every decision with KPIs and disclose the results.

How to Approach a Vendor about a Scorecard

If supplier scorecards are new to your firm and your vendor relationships, invite your suppliers into the process early on and portray the change as a partnership to ensure optimal working relationships and results. Do the following to achieve the best results at each stage of the process:

- Prior to Implementation: Before implementing scorecards, have a casual discussion with your vendors.

- Orientation: Provide a written notice outlining the program’s objectives, KPIs, and measures.

- Meeting with Vendors: Set up meetings to go over any concerns your suppliers may have.

- Rollout: To iron out any bugs, perform a soft deployment. Check-in with vendors on a regular basis to see how the new standards are working for them and how they feel about their scoring.

Finally, it all comes down to interacting with suppliers. Collaborate to track and measure progress.

Frequently Asked Questions

How can Balanced Scorecards be implemented in organizations?

The Balanced Supplier Scorecard is a versatile tool that may be used by any type of organization: Large, medium and small enterprises must meet sales and profit targets for their shareholders. Based on the availability of limited resources, non-profit organizations can execute their social aims. Government entities/departments to enable public/community delivery.

How is the scorecard being implemented? What are the challenges?

There are several hurdles to guaranteeing the scorecard’s proper implementation. The main one, though, is a lack of senior management commitment. “What matters to the boss is essential to me.” Chances are, if the CEO or GM is not committed to ensuring that the scorecard is reported monthly, it will not be reported!

To report the scorecard, is it necessary to implement an IT system?

Though not entirely necessary, it is advantageous to adopt an IT system to automate scorecard reporting. It makes the process of physically compiling data easier. Only data available on the legacy/ERP system, however, can be captured from the system. Certain measures (for example, the Customer Satisfaction Index) may have to be manually compiled and reported into the scorecard. There is numerous software available for this purpose, depending on the size and needs of the firm.

What is supplier scorecard software?

While the supplier scorecard process is critical, it may also be extremely time-consuming. This is especially true if everything a provider does or does not do is manually noted on a spreadsheet. The better method to deal with the situation is to automate the procedure. The good news is that there is supplier scorecard software available.

These have tools that can evaluate and rate vendors with less effort and in a fraction of the time. In truth, supplier scorecard software is intended to aid in a key step for your success. In many circumstances, you may use it to get a score ranging from one to one hundred, allowing you to examine how each unique supplier compares to your chosen set of criteria.