10 Steps to Effective Supplier Selection

In today’s global marketplace, effective supplier selection or vendor selection is crucial for the success of any organization. Having a robust supplier selection ensures a smooth supply chain, high-quality products or services, competitive pricing, and reliable delivery.

However, the process of supplier selection can be complex and requires careful consideration of various factors. This article aims to provide a detailed guide to the supplier selection process, outlining the key steps and considerations involved and discussing the importance of having a supplier selection mechanism for your organization.

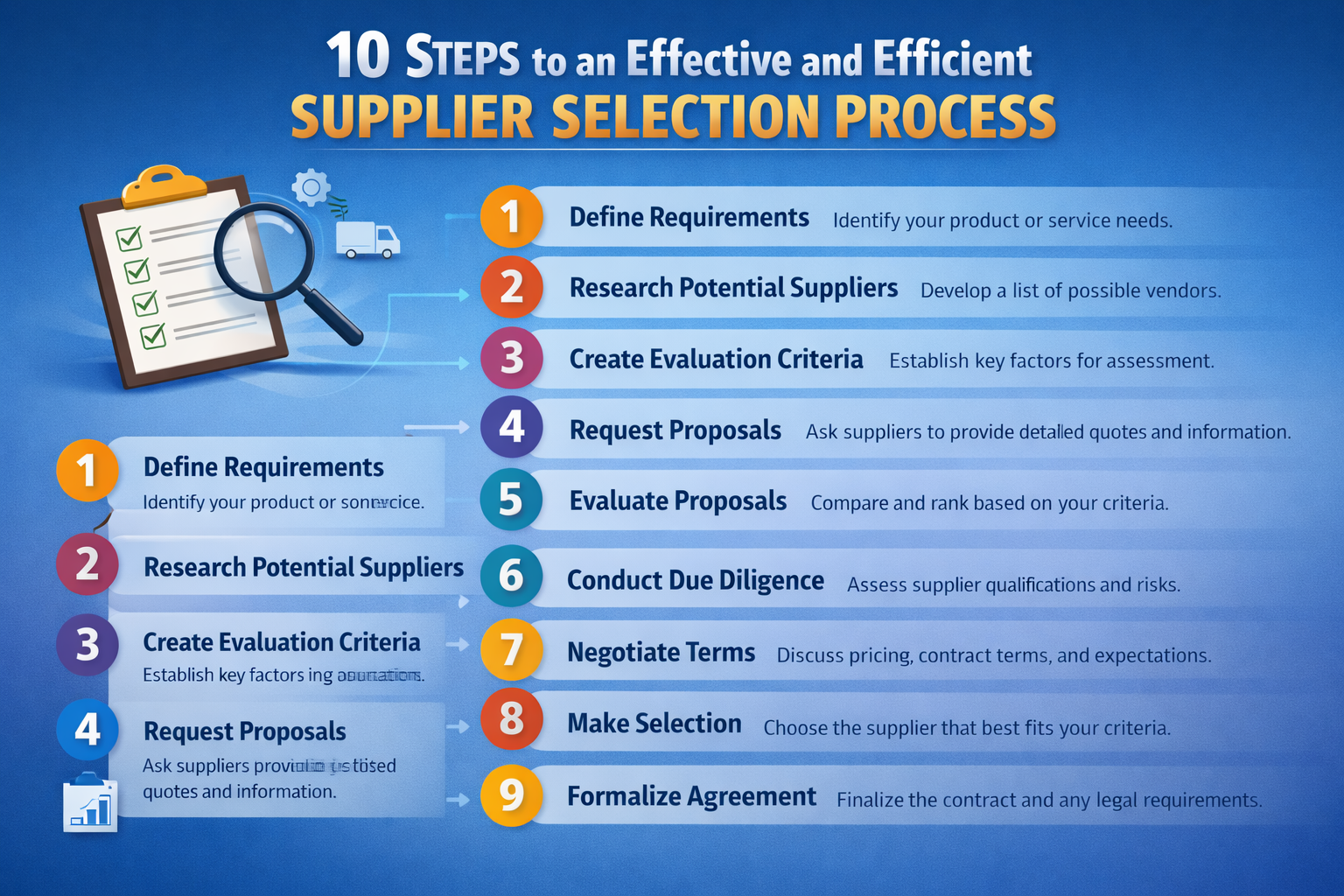

10 Steps to Effective and Efficient Supplier Selection Process

Step 1: Determine Supplier Requirements:

Clearly defining your supplier requirements is the first step in the strategic supplier selection process. This entails identifying the products or services required, as well as the quality standards, lead times, cost expectations, and any other supply chain considerations. Engaging key stakeholders from various departments ensures a comprehensive supplier sourcing strategy.

Step 2: Supplier Evaluation Criteria:

Following the establishment of the requirements, a set of supplier evaluation criteria to evaluate possible suppliers. These requirements could include things like a supplier’s financial stability, ISO certifications, production capacity, on-time delivery performance, regulatory compliance, supplier risk assessment, ethical standards, and cultural fit with your organization. Assigning weight to each criterion helps in strategic supplier evaluation.

Step 3: Supplier Identification:

You can begin with locating possible suppliers after determining the assessment criteria. This can be accomplished through a variety of techniques, including supplier databases, trade exhibits, web directories, competitive market research, and industry referrals. A comprehensive supplier discovery process ensures a diverse pool of vendors, minimizing supply chain disruptions.

Step 4: Supplier Pre-qualification:

Before conducting a detailed evaluation, it is advisable to pre-qualify suppliers based on their initial fit with your requirements. This can be done through a preliminary assessment of their capabilities, financial stability, and compliance with regulatory and legal requirements. This step helps eliminate unqualified vendors early, optimizing procurement efficiency.

Step 5: Request for Proposal (RFP):

The next step involves sending a formal Request for Proposal (RFP) to the shortlisted suppliers. The RFP should provide detailed information about your organization, requirements, evaluation criteria, and expectations. It also requests supplier capability statements, logistics strategies, and customer references to ensure transparency in supplier procurement.

Step 6: Supplier Evaluation:

Once the responses to the RFP are received, a thorough evaluation of each supplier is necessary. This includes benchmarking supplier pricing, auditing manufacturing processes, performing site inspections, supplier scorecard assessments, and evaluating supplier KPIs like defect rates and on-time delivery metrics. It is essential to assess each supplier against the established evaluation criteria and compare their capabilities, offerings, and value proposition.

Step 7: Supplier Selection:

Based on the evaluation, a shortlist of suppliers who best meet your requirements should be created. The final selection should consider factors such as quality, reliability, price competitiveness, delivery capabilities, financial stability, and the supplier’s ability to collaborate effectively. It is important to involve key stakeholders in the decision-making process to ensure alignment with organizational goals and objectives.

Step 8: Negotiation and Contracting:

Once the preferred supplier(s) are identified, negotiations can commence. This involves discussing pricing, terms and conditions, service level agreements, intellectual property rights, and any other relevant contractual aspects. It is crucial to establish clear communication channels, dispute resolution mechanisms, and performance monitoring mechanisms within the contract to ensure a mutually beneficial relationship.

Step 9: Utilizing a Scorecard to rate your suppliers

A supplier scorecard is a structured evaluation tool that uses predefined criteria and metrics to objectively assess and compare suppliers. It enables data-driven decision-making in supplier selection and management, promoting transparency and continuous improvement in the supply chain.

Step 10: Supplier Performance Monitoring:

Implement a supplier performance monitoring system that includes quarterly business reviews (QBRs), real-time procurement analytics, and key performance indicator (KPI) tracking. This ensures supplier accountability, continuous improvement, and supply chain risk management for long-term supplier relationships.

Why is having a Supplier Selection process essential for your company?

-

Quality Assurance:

Choosing the appropriate suppliers guarantees that the business will obtain products and services of the desired caliber. Organizations can assess suppliers’ qualifications, accreditations, quality assurance procedures, and track records during the selection process to make sure they adhere to the necessary requirements.

-

Cost management:

During the procurement process, businesses can explore multiple supplier pricing models and negotiate with potential vendors to achieve cost savings. Conducting competitive supplier analysis allows organizations to identify cost-effective suppliers who offer the best balance of price, quality, and service, ensuring procurement efficiency without compromising quality.

-

Risk Reduction:

Selecting the right suppliers is crucial for businesses to mitigate various supply chain risks. These include quality and delivery risks, which can lead to customer dissatisfaction and operational disruptions, and financial and capacity risks, potentially causing supply shortages. Compliance, ethical, and geopolitical risks can result in legal issues, reputation damage, and sourcing disruptions. Innovation, relationship, and strategic risks can limit growth opportunities and negatively impact supply chain performance. Therefore, evaluating suppliers’ stability, capacity, and performance history is essential for a robust supply chain.

-

Innovation and Expertise:

Right supplier selection provides innovation, expertise, and technology improvements to the organization. Organizations may obtain cutting-edge solutions and keep one step ahead of rivals by analyzing suppliers’ technical proficiency, sector knowledge, and history of innovation.

-

Ethical and Social Responsibility:

Organizations are putting more of an emphasis on socially and ethically acceptable sourcing techniques. Organizations can evaluate whether prospective suppliers follow ethical criteria like fair labor practices, environmental sustainability, and adherence to relevant rules through the supplier selection process. By doing this, it is made sure that suppliers share the commitments and values of the company.

-

Relationship Development:

Through the supplier selection process, businesses can build relationships with suppliers based on respect, clear communication, and cooperation. choosing vendors who share the organization’s objectives and values, a basis for long-term relationships is built, encouraging strategic alliances and synergies.

Conclusion

The supplier selection process is a critical component of effective supply chain management for every company.

Your business will be successful if you strategically consider each of the suppliers in your network and take the time to consider all of your possibilities.

It’s important to note that the specific steps and criteria may vary depending on the organization, industry, and complexity of the procurement needs. The process should be tailored to meet the unique requirements of each situation.

FAQs

What are the 10 steps in an effective supplier selection process?

The steps include:

- Determine Supplier Requirements

- Establish Supplier Evaluation Criteria

- Identify Potential Suppliers

- Pre-qualify Suppliers

- Issue Request for Proposal (RFP)

- Evaluate Supplier Proposals

- Select Preferred Suppliers

- Negotiate Terms and Conditions

- Finalize Contracts

- Monitor Supplier Performance

How do you evaluate suppliers effectively?

Effective evaluation involves assessing suppliers against predefined criteria such as quality, cost, delivery reliability, compliance, and financial stability. Utilizing tools like supplier scorecards can aid in this process.

Why is supplier pre-qualification important?

Pre-qualification ensures that suppliers meet your basic requirements before engaging in detailed evaluations, saving time and resources by eliminating unsuitable candidates early in the process.

What should be included in a supplier Request for Proposal (RFP)?

An RFP should detail your organization’s requirements, expectations, evaluation criteria, and timelines. It serves as a formal invitation for suppliers to submit their proposals.

How do you monitor supplier performance post-selection?

Monitoring involves tracking key performance indicators (KPIs) such as on-time delivery, quality standards, and compliance. Regular reviews and audits help maintain supplier accountability and performance.

What is the first step in supplier selection?

The first step is determining your supplier requirements, which includes defining the products or services needed, quality standards, lead times, and cost expectations.

How do you identify potential suppliers?

Potential suppliers can be identified through industry directories, trade shows, referrals, and online research. It’s important to consider factors like reputation, capacity, and experience.

What criteria are used to evaluate suppliers?

Common evaluation criteria include cost, quality, delivery reliability, compliance with regulations, financial stability, and alignment with your organization’s values and objectives.

Why is supplier negotiation important?

Negotiation ensures that both parties agree on terms that are mutually beneficial, covering aspects like pricing, delivery schedules, and service levels, which are crucial for a successful partnership.

How often should supplier evaluations be conducted?

Supplier evaluations should be conducted regularly, typically annually, to ensure ongoing compliance with agreed terms and to identify areas for improvement.